With the rise in environmental concerns, companies of all sizes cannot afford to neglect their on-site impact. Understanding how your production process interacts with nature around you and learning to find a balance is essential to running a successful business. You could use countless waste management and sensitisation strategies, but here are four worth highlighting.

Saving the environment

No production process is perfect, and waste is a reality most outfits come to accept. Waste management requires much more planning and decisiveness than people think. How you handle your waste could change depending on its type.For instance, detecting radioactivity on a radiation monitoring system would prompt you to carefully handle your waste. Thankfully, there are simple strategies that you could try to help optimise your current waste management setup.

Encouraging waste reduction and reuse

Beyond the obvious environmental benefits of this practice, your company could save a lot on source materials by utilising a higher percentage during production. Excesses piled up at the tail end of production can be prepped and fed back into the system to get more out of what you have. When you go out of your way to promote this approach, less is left for disposal, significantly reducing your outfit’s environmental impact.

Investing in advanced waste sorting technology

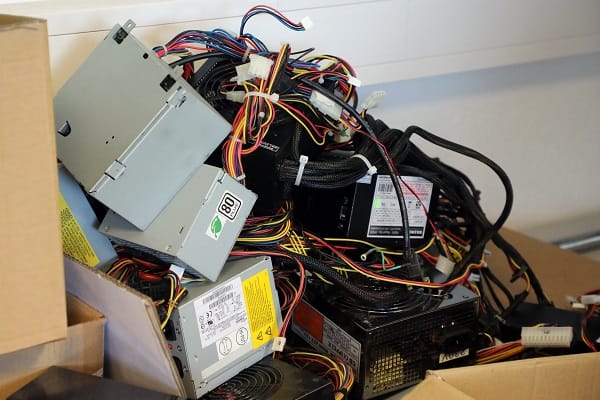

Effective recycling starts at the sorting level, which can take time to be done properly. Thankfully, this process can be expedited by using some of the sorting technology currently available on the market. One major example would be optical sensors, which can accurately differentiate and sort types of recyclable material.

A less popular solution would be chemical detection, which is less researched and is still in the budding stages of development. Either way, these solutions improve sorting accuracy, producing higher-quality recycled material that is valuable and usable in production.

Education and engagement in sound practices

A production plant is only as green as its lowest-level employee. One cannot expect a business to be environmentally friendly when they haven’t taken the time to properly inform employees of the right waste disposal protocols. This is easier to do with smaller setups and fewer employees. However, it is also possible with bigger firms. It boils down to understanding the importance of proper waste management and making the right investments for change.

Adequate planning at every step of production

Waste largely consists of overheads in production materials. When overestimates are made, facilities are left with run-off that cannot be reused without processing. This overhead can be significantly reduced with adequate planning.

This might involve studying each production stage and establishing the materials needed for a finished product. However, once these amounts are known, they should be strictly adhered to as much as possible. This form of waste management goes back to before the waste is created and tries to make the subsequent situation as manageable as possible.

Conclusion

Sales do not just measure success. Your business could be ruined by overlooking how waste is handled. Thankfully, you’re already on the right track. By adequately considering some of the management strategies discussed and tailoring an approach to fit your business, you can please both the environment and your interests. It’s all about finding balance.